Vacuum drying is the process of removing bulk moisture from a wet solid by exposing the mixture to vacuum. Drying is an essential operation in many different processes and is found in the food processing, pharmaceuticals, agriculture, powders and textiles industries. Vacuum blending and mixing use similar principles as in vacuum drying, so Wintek often sells process vacuum systems in these markets as well.

How Vacuum Dryers Work

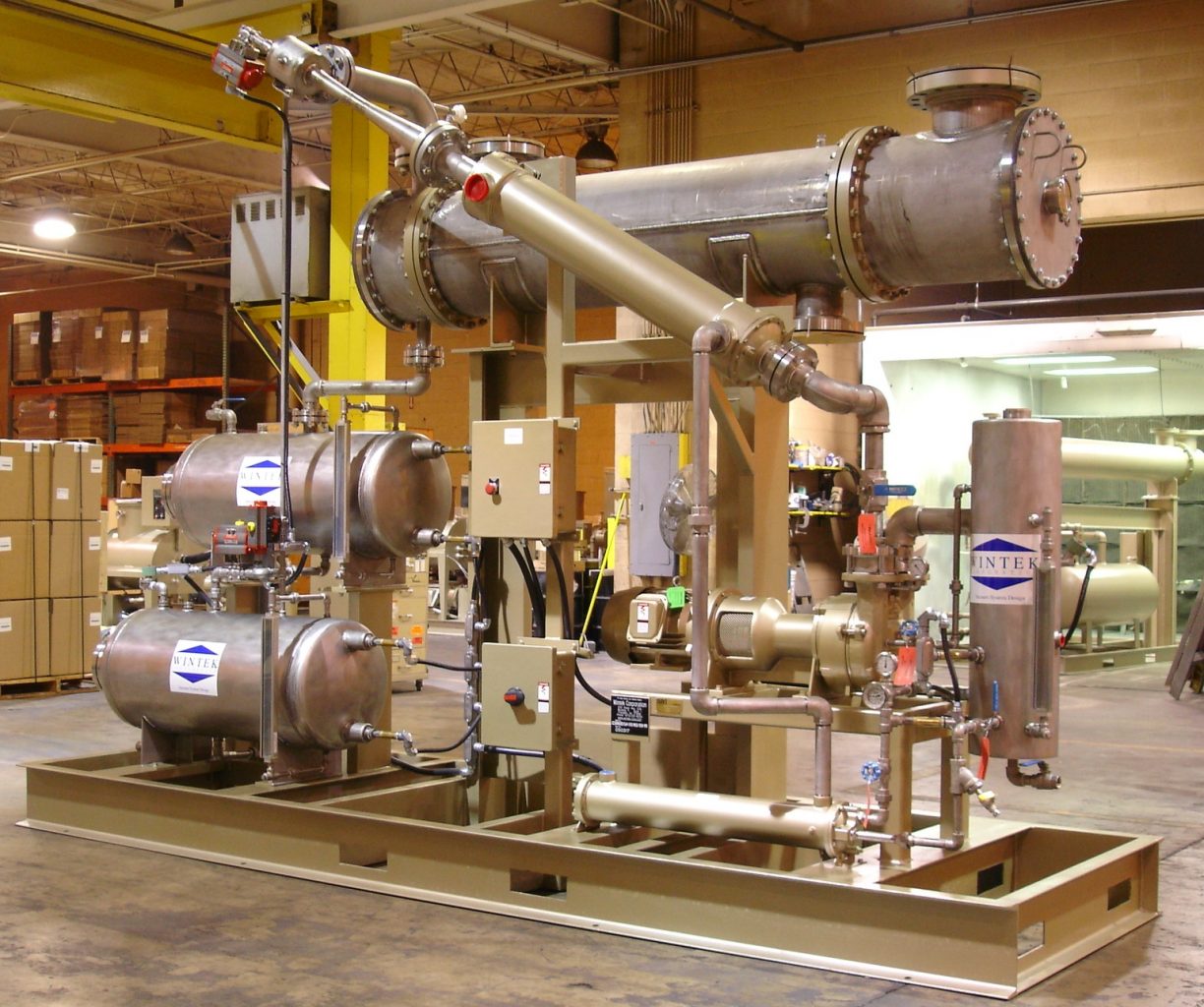

Traditional dryers use two main driving forces to remove moisture: elevated temperatures and stripping gasses to saturate and remove vapors. Adding vacuum as a third force to the process greatly increases the overall efficiency of a dryer. A vacuum system lowers the pressure inside a large drying vessel. As the pressure within the vessel lowers to the vapor pressure of the liquid, the moisture will vaporize, leaving a dry product. Heaters installed on the vacuum dryer increase the temperature of the vessel. This increase in temperature coupled with the decrease in pressure allows for very high evaporation rates to occur. Once in vapor form, the vacuum system removes the moisture from the dryer. Depending on the customer’s desires, a heat exchanger condenses and a receiver tank collects the solvent.