Vacuum impregnation is the process of decreasing porosity in products to lower the chance of field failures in applications that are exposed to high pressure. Improper sealing will allow gasses and fluids to pass through the pores on the surface of many products causing leaks. Vacuum impregnation helps to fill out these pores.

First, the product is placed in an air-tight vessel. The vacuum removes the entrapped air from the pores. Once the air is removed, a sealant is pumped into the vessel at a high pressure. The high pressure forces the sealant into the pores on the surface of the product. The product then undergoes washing and curing steps which seal the pores effectively. As a result, there is a decrease in fluid losses, leakages, and structural failures.

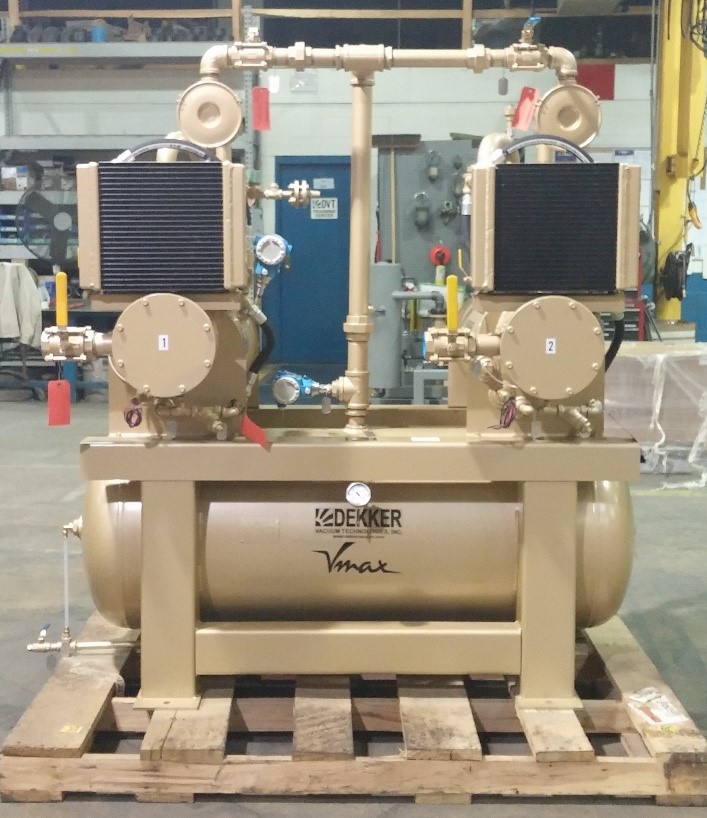

Since the vacuum pump should only be handling clean air, Wintek would generally recommend either a rotary vane or an oil-sealed liquid ring vacuum pump. Both pumps are great at handling clean air and can reach vacuum levels required for impregnation (~1 Torr for the rotary vane pumps, ~23 Torr for the oil-sealed liquid ring vacuum pumps).